Measuring and monitoring the chemicals used to treat the water in the post-harvest process is critical for success. Sampling and adding chemicals by hand increases labor and exposes personnel to aggressive chemicals. Also, the process is subject to human error and can result in expensive chemical overuse.

Automated systems for sampling and injecting chlorine, hydrogen peroxide, and PAA into the wash systems effectively control the process. Unfortunately, they also tend to be very expensive.

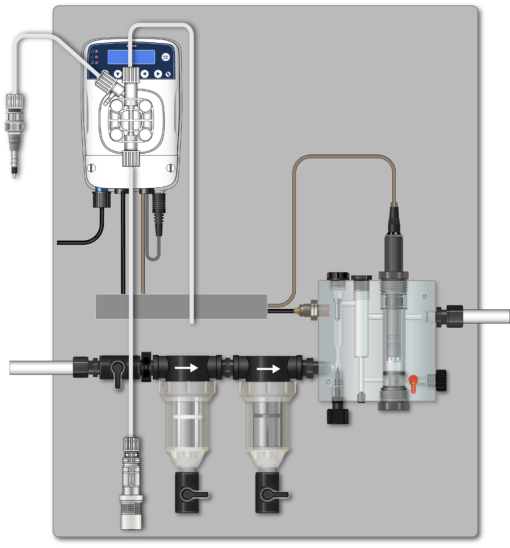

Dilution Solutions offers a cost-effective method of sampling and controlling the level of disinfecting chemicals used in recirculated process water.. The system consists of a ready-to-mount control panel with an Etatron microprocessor integrated electric pump in conjunction with an electrode in a sampling line. The electrode continuously monitors the concentration and signals the Etatron to add chemicals when the concentration falls below the set point. This plug-and-play solution comes complete with flush valves, a safety proximity switch, alarm function, and filters.

The heart of the system is the Etatron pump. This unique design integrates the process control function into the pump itself, allowing it to measure and replenish the chemistry continuously. The pump’s display shows the chemical concentration in real time, and its PVDF head and Teflon diaphragm resists chemical attack. Tailoring the system to your specific needs is easily accomplished by accessing the pump’s menu driven program through the push button display.

Dilution Solutions Chlorine Control Panel

The control panel is available in four different configurations to match your choice of post-harvest chemicals. There are versions available to inject inorganic chlorine, hydrogen peroxide, PAA, and inorganic chlorine with ph.

Contact us at 1-800-451-6628 for more information on the post-harvest chemical control panel.