President's Day Savings: Use code PRES8 for 8% off. Ends 2/20 View deal

Art. No.: dt_pr34-npt

Art. No.: dt_pr34-npt

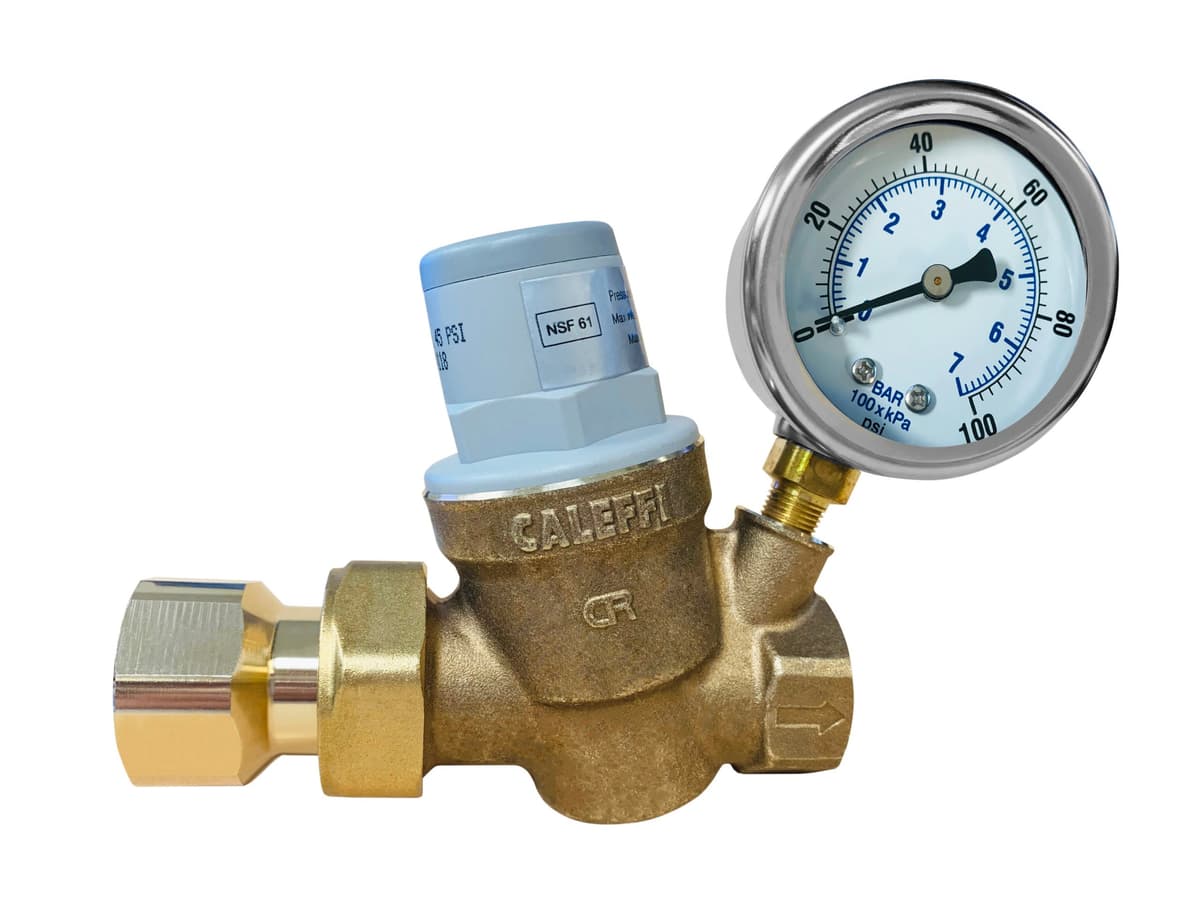

3/4" NPT low-lead brass body with durable stainless steel gauge with 1/8" brass threads.

Features:

3/4″ NPT low-lead brass body, durable stainless steel gauge with 1/8″ brass threads.

3/4″ Water Pressure Regulator for Your Dosatron Installation

A 3/4″ Pressure Regulator is crucial for your Dosatron installation. It keeps water pressure steady, which is vital for accurate chemical dosing. Without it, pressure changes can cause problems. Here’s why it’s so important:

Ensures Consistent Performance

Dosatron injectors need steady water pressure to work right. If the pressure changes too much, the dosing can be wrong. This means you might end up using too much or too little of your chemicals. A pressure regulator keeps the pressure constant, ensuring the injector works correctly all the time.

Protects Your Equipment

High water pressure can damage your Dosatron. It can wear out the parts quickly, leading to costly repairs or replacements. Low pressure can make the injector malfunction, causing it to stop working properly. A pressure regulator keeps the pressure within a safe range, protecting your equipment from damage and extending its life.

Maintains Dosage Accuracy

Dosatron Injectors are designed to deliver precise doses of chemicals based on a specific pressure range. If the pressure is too high or too low, the dosage can be off. A pressure regulator makes sure the pressure stays within this range, ensuring accurate chemical mixing and delivery. This accuracy is crucial for effective use of the chemicals.

Enhances System Efficiency

A pressure regulator improves the overall efficiency of your dosing system. Without it, pressure fluctuations can cause clogs or blockages. This can slow down or stop the system, leading to downtime and lost productivity. By keeping the pressure steady, the regulator helps the system run smoothly, reducing maintenance needs and improving efficiency.

Maximizes Chemical Longevity

When chemicals are mixed and delivered at the correct concentrations, they work better and last longer. If the pressure is too high or too low, the chemical mix can be wrong. This can lead to waste, either by using too much chemical or by not using enough. A pressure regulator ensures the correct mix, maximizing the effectiveness and longevity of your chemicals.

How a Pressure Regulator Works

A pressure regulator reduces the water pressure from a high level to a lower, constant level. It has a spring and a diaphragm that adjust to changes in pressure. When the incoming pressure is too high, the diaphragm moves to restrict the flow, lowering the pressure. When the incoming pressure is too low, the diaphragm moves to allow more flow, raising the pressure.

This automatic adjustment keeps the pressure steady, ensuring your Dosatron injector gets the right pressure it needs to work correctly.

Choosing the Right Pressure Regulator

When choosing a pressure regulator for your Dosatron installation, consider these factors:

Installation Tips

Installing a pressure regulator is straightforward, but here are some tips to ensure a successful installation:

Benefits of Using a Pressure Regulator

Using a pressure regulator with your Dosatron installation offers many benefits:

Issues You May Face Without a Pressure Regulator

Without a pressure regulator in your Dosatron installation, you may encounter several significant issues that can affect the performance and efficiency of your system. Here’s a closer look at these potential problems:

1. Inaccurate Dosing

Pressure fluctuations can cause your Dosatron injector to deliver incorrect chemical doses. The Dosatron system relies on a steady pressure to mix chemicals accurately with water. If the pressure is too high or too low, the ratio of chemical to water will be off. This can lead to over-dosing or under-dosing, both of which can have serious consequences:

2. Equipment Damage

High water pressure can quickly wear out the parts of your Dosatron injector. The internal components are designed to operate within a specific pressure range. When the pressure exceeds this range, it can cause excessive stress on the parts, leading to:

3. System Downtime

Pressure changes can cause clogs or malfunctions in your dosing system. When the pressure fluctuates, it can lead to inconsistent flow rates, which in turn can cause:

4. Increased Costs

Incorrect dosing and equipment damage can lead to higher working costs. The expenses associated with fluctuating pressure can quickly add in:

5. Efficiency

Unsteady pressure reduces the overall efficiency of your dosing system. Efficiency in a Dosatron system is achieved when the injector can operate smoothly and consistently at the desired pressure. Without a regulator:

Real-World Examples

Many industries rely on Dosatron injectors for precise chemical dosing. Here are some examples:

Additional Considerations

A 3/4″ Pressure Regulator is essential for any Dosatron installation. It ensures consistent water pressure, which is crucial for accurate chemical dosing, protecting equipment, and maintaining system efficiency.

By keeping the pressure steady, the regulator helps you get the most out of your Dosatron injector and the chemicals you use. Whether you are in agriculture, livestock, water treatment, or any other industry, a pressure regulator is a smart investment that pays off in accuracy, efficiency, and cost savings.